Why cutting running shoes in half is key to measuring midsole softness

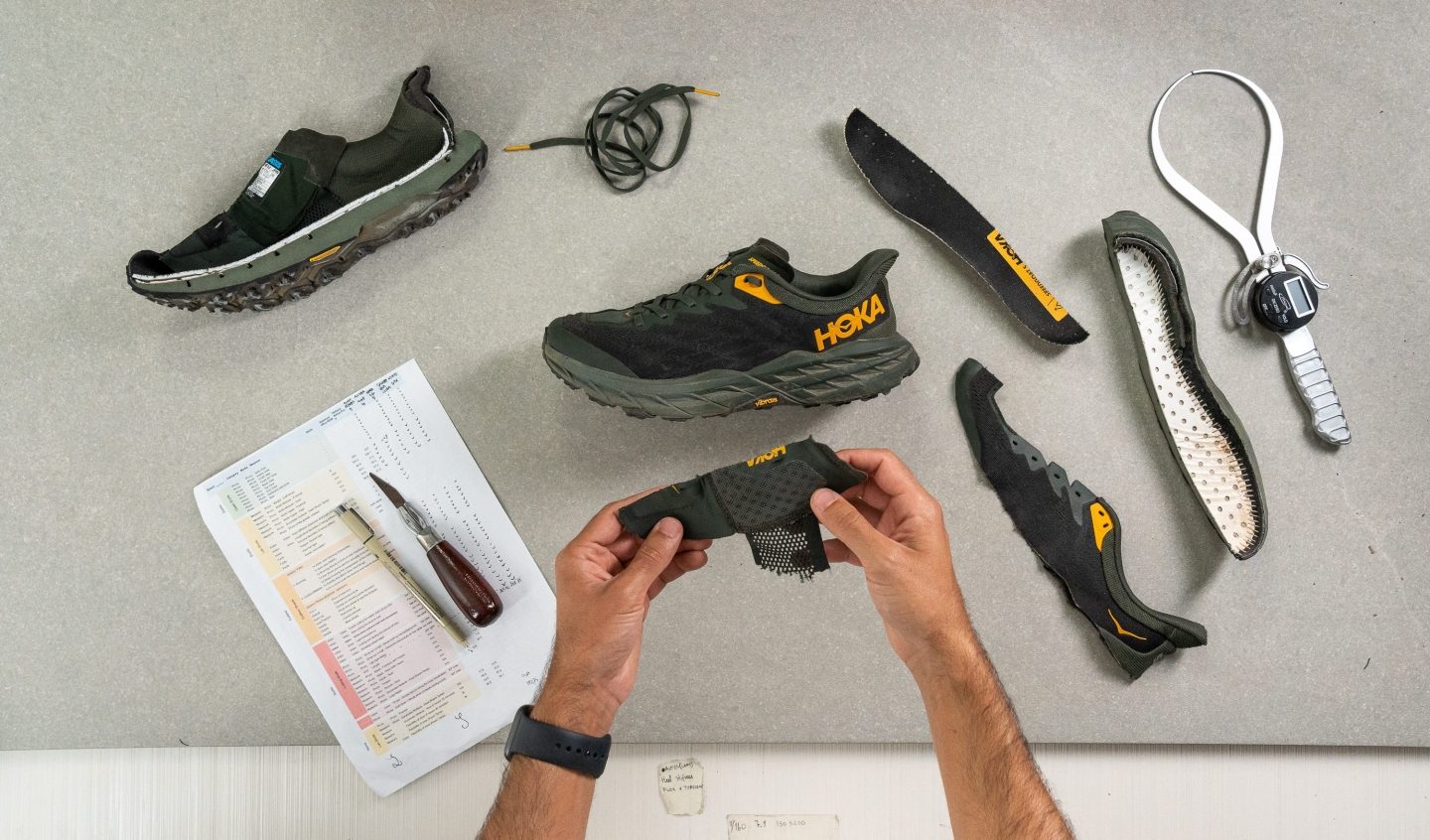

In the RunRepeat lab, we ensure precise midsole softness measurements by first cutting the shoe in half.

This approach enables us to apply the durometer directly onto the actual foam for getting accurate results. It's a costly process, especially as we purchase all our shoes without accepting any from brands, and that’s probably why every running website or YouTube channel just tests the durometer on the exterior of the midsole. But there's a problem with that.

Applying the durometer on the outside of a running shoe can be misleading, as it always fails to accurately capture the midsole's true softness.

This inaccuracy stems from the hard, protective outer layer present in most running shoes, which varies significantly from one shoe to another. Furthermore, the outer surface of shoes often has numerous contours and bumps. Given the sensitivity of durometers, even a slight angle variation can lead to significant changes in the results.

Unpacking insights from interior and exterior durometer readings in midsoles

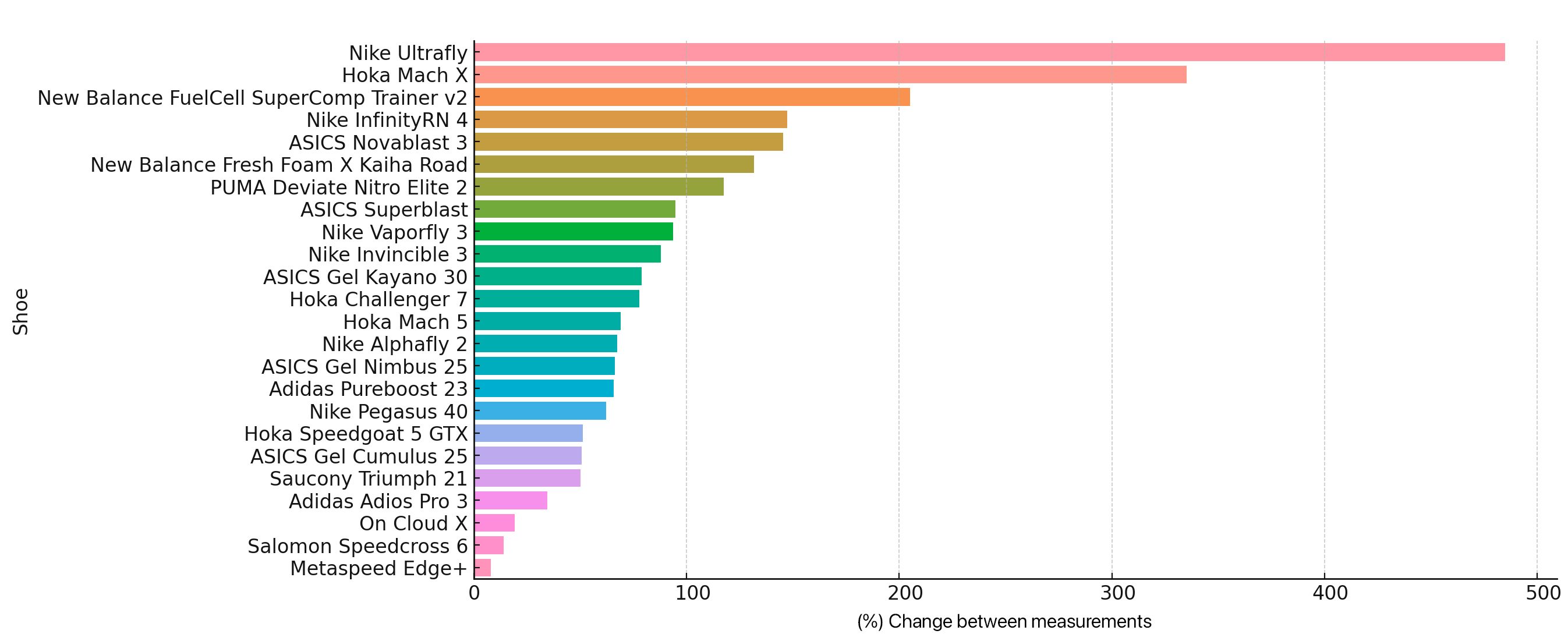

We believe actions speak louder than words, and our lab is where we uncover the facts. We've specifically tested 24 shoes for this guide, both internally and externally, to prove why exterior measurements fall short in revealing the true nature of a running shoe.

The chart above clearly illustrates the significant disparities between interior and exterior measurements, ranging from a 24% difference in the ASICS Metaspeed Edge+ to a staggering 485% in the Nike Ultrafly.

These variations are not coincidental. The ASICS, designed as a racing shoe, doesn’t sport any hard protective layer to minimize weight, while the Ultrafly, tailored for trail running, incorporates substantial protection to endure rugged terrains.

Additionally, for an in-depth look, you can check out the detailed raw data in the table below. Keep in mind, a lower number indicates a softer material:

| Shoe | HA - Interior | HA - Exterior | Difference |

| Nike Ultrafly | 10.0 | 58.5 | 485% |

| Hoka Mach X | 10.0 | 43.5 | 335% |

| New Balance FuelCell SuperComp Trainer v2 | 10.0 | 30.5 | 205% |

| ASICS Novablast 3 | 13.5 | 40.0 | 196% |

| Nike InfinityRN 4 | 12.5 | 35.5 | 184% |

| New Balance Fresh Foam X Kaiha Road | 13.5 | 37.5 | 178% |

| ASICS Superblast | 17.5 | 46.5 | 166% |

| PUMA Deviate Nitro Elite 2 | 14.0 | 37.0 | 164% |

| Nike Vaporfly 3 | 16.5 | 42.0 | 155% |

| Nike Alphafly 2 | 20.0 | 47.0 | 135% |

| Hoka Challenger 7 | 17.0 | 39.5 | 132% |

| ASICS Gel Kayano 30 | 16.5 | 38.0 | 130% |

| Nike Invincible 3 | 14.5 | 33.0 | 128% |

| ASICS Gel Nimbus 25 | 18.0 | 39.5 | 119% |

| Nike Pegasus 40 | 17.5 | 36.5 | 109% |

| Hoka Speedgoat 5 GTX | 20.5 | 42.0 | 105% |

| Hoka Mach 5 | 15.0 | 30.5 | 103% |

| Adidas Pureboost 23 | 13.5 | 25.5 | 89% |

| ASICS Gel Cumulus 25 | 17.5 | 33.0 | 89% |

| Saucony Triumph 21 | 17.0 | 31.5 | 85% |

| Adidas Adizero Adios Pro 3 | 20.5 | 35.0 | 71% |

| On Cloud X | 33.0 | 54.0 | 64% |

| Salomon Speedcross 6 | 34.5 | 51.0 | 48% |

| ASICS Metaspeed Edge+ | 30.3 | 37.5 | 24% |

Please note: You can download each picture of our exterior measurements from this link. If you're interested in cut-in-half measurements, visit the individual shoe pages linked above.

Three examples proving why cutting shoes is essential

To better understand these significant differences among running shoes, we will closely examine a three standout examples.

ASICS Superblast

As we said before, some models feature exceptionally hard protective layers—like trail running shoes—while others like racing shoes might have softer ones, greatly influencing the external durometer readings.

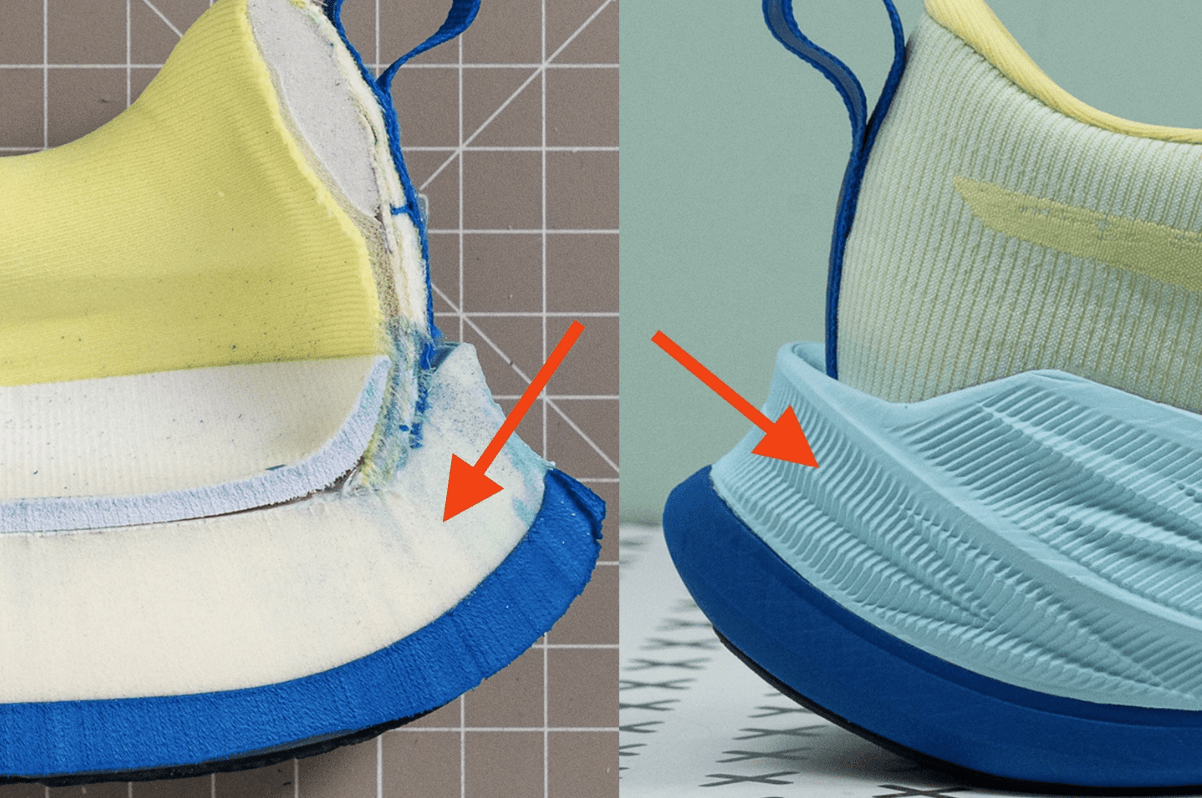

The ASICS Superblast serves as a prime example of how external measurements can be deceptive. When we cut the shoe in half, the true nature of the midsole is revealed, showing that the external layer bears no resemblance to the actual FF Turbo main foam inside.

- Internal measurement (left): 17.5 HA

- External measurement (right): 46.5 HA

- Difference: 166%

The contrast between the accurate measurement taken directly on the actual foam and the measurement made on the exterior of the shoe is striking in the Superblast. But there's more to come.

Nike Ultrafly

The Nike Ultrafly also stands out as a terrific example of the necessity for midsole measurements to be taken from cut sections of running shoes. This premium trail shoe, featuring a 10.0-HA ZoomX foam, is known for its ultra-soft ride. However, our external measurement indicated a mind-blowing number of 58.5 HA. The reason behind this discrepancy lies in the shoe's construction.

ZoomX foam, based on Pebax and known for its delicacy, raised concerns about the shoe's durability on rugged trails with sharp rocks and similar hazards. To address this, Nike encased the ZoomX in a robust, tightly woven outer fabric, designed to protect the foam.

Consequently, the external measurement of softness is misleadingly high, reflecting the protective layer rather than the actual foam itself.

When we cutted in half the shoe, we conducted a second measurement directly on the actual ZoomX foam. This revealed a far more logical reading of 10.0 HA, aligning with the plush running experience the shoe is known for. Now everything just clicks.

On Cloud X and Hoka Mach X

| Shoe | HA - Interior | HA - Exterior | Difference |

| On Cloud X | 33 | 54 | 64% |

| Hoka Mach X | 10 | 43.5 | 335% |

Although the “X” in their names might suggest a link, the Cloud X and Mach X shoes share little in common, except for one crucial aspect: they perfectly illustrate why our cut-in-half measurements are the ones to trust.

As highlighted in the table, the Cloud X is incredibly firm with a hardness of 33 HA, making it one of the stiffest shoes we've tested. In contrast, the Mach X is remarkably soft at just 10 HA.

But here's the catch, if we hadn't cut the shoes in half—rendering them unusable in the process—and instead measured the softness externally, the results would paint a misleading picture. Internally, there’s a vast 230% difference in softness between the two shoes, but externally, it appears as a mere 24% difference.

The Hoka Mach X is not just 24% softer than the Cloud X, a fact evident to anyone running even five minutes in them. However, if one relies on external durometer readings, the result is a gross misrepresentation of what each shoe truly offers.

Adidas Adizero Adios Pro 3

The situation with this Adidas competition shoe is interesting, as it presents a stark contrast to the cases we've previously discussed.

In this instance, Adidas prioritizes weight reduction, leading to a design choice where durability is somewhat compromised. This approach involves less protection for the exterior layer of Lightstrike Pro foam, a decision that sheds light on the results we see:

- Internal measurement: 20.5 HA

- External measurement: 35.0 HA

- Difference: 71%

From the image above, you'll notice that there's hardly any noticeable change in the foam's appearance after the shoe has been cut in half. Additionally, we can confirm that the feel of the foam is almost identical to the touch.

This similarity is why this shoe stands out as one of the few with less than a 100% difference in softness between the interior and exterior measurements.

How durometers measure running shoe softness

You might be thinking: "Alright, I get why you guys at RunRepeat need to cut the shoe in half to check its softness, but what about the tool used for this measurement? How exactly does that small device work?"

A durometer is an instrument designed to measure the softness of materials. It employs a scale called Shore hardness, which has various versions like Shore A and Shore D, each tailored for different types of materials. For measuring the softness of running shoe midsoles, the Shore A scale is most appropriate, and it’s the one we use.

The durometer operates by exerting a standardized force to create an indentation on the material's surface, followed by measuring the depth of this indentation. The depth achieved directly reflects how resistant the material is to indentation, which in turn correlates to its softness level. Essentially, a deeper indentation signifies a softer material, as it indicates less resistance to the applied force.

The dimensionless nature of durometer measurements

It’s crucial to understand that softness is a relative, dimensionless measurement. This means that a material's hardness is determined in relation to the hardness of other materials, but only when measured using the same durometer scale. The comparison is valid and meaningful within this context, as it maintains a consistent reference point for evaluation.

Think of a durometer like a special ruler that doesn't use regular units like inches or centimeters. Instead, it pushes a pointy tip into a material, like the foam in a running shoe, and sees how deep it can go.

The deeper it goes, the softer the material. But the measurement it gives doesn't have a unit like "inches." It just gives a number on its own scale (HA), like a score in a basketball game. This score tells us how hard or soft something is compared to other things measured on the same scale, but it's not a measurement with a unit like length or weight.

Furthermore, two different durometers, even when measuring on the Shore A scale, might not deliver exactly the same readings. In an ideal scenario, they should provide very similar results, but in practice, there can be variations. These discrepancies arise due to factors like calibration differences, wear and tear, and variations in manufacturing. Each durometer may have a slightly different sensitivity or response, leading to different readings.

This variation is why consistency in using the same durometer for comparative measurements is crucial for accuracy.

Final thoughts

While measuring midsole softness with a durometer on a shoe that's been cut in half is not an absolutely perfect method for gauging a shoe's softness—since it doesn't account for factors like the outsole rubber or the influence of a carbon plate—it remains the best approach as of today. And this method is our go-to until a more advanced or accurate way of measuring midsole softness is developed.

However, it's crucial to understand that this effective method applies only to shoes that have been cut in half. As we've shown in this article, attempting to measure midsole softness from the exterior leads to unreliable and imprecise results. Such inaccuracy not only misleads runners, but can also contribute to them making wrong choices when purchasing the next pair running shoes.